Metal Cladding is a process of bonding or attaching one metal to another. Cladding is often used to protect buildings from the elements and improve their appearance.

The greatest strength of metal cladding is its durability. Metal is a solid material that can withstand a lot of wear and tear. It is also resistant to fire, making it an ideal choice for cladding buildings in areas where wildfires are a concern.

Metal Cladding Systems

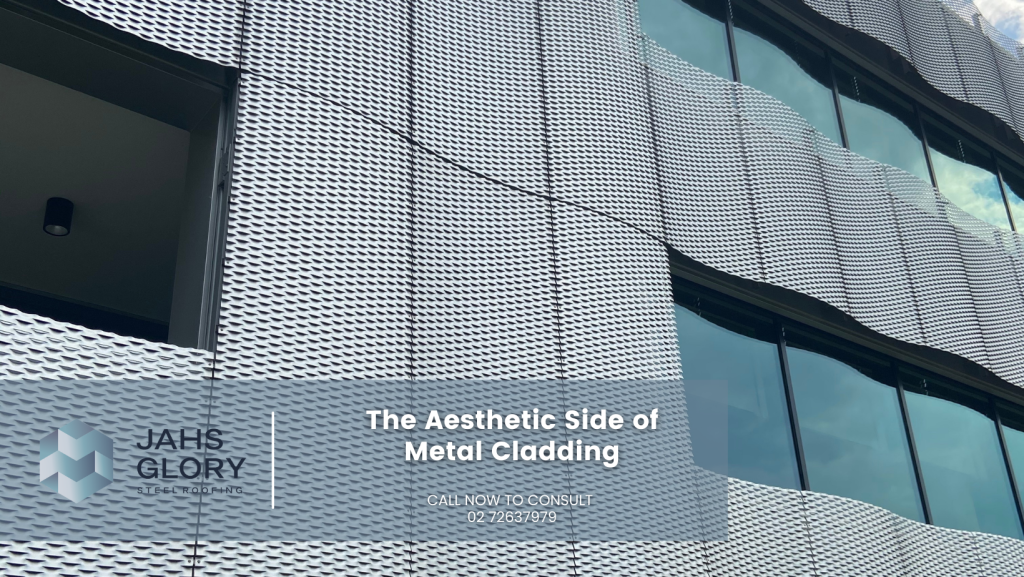

Metal is widely utilised for non-structural, rain-screen cladding systems, where the objective is to give both weather protection and a visually appealing external appearance. Metal panels may be joined and fastened to a structure in many ways due to their foldable, pliable nature, with each method having various benefits in terms of construction complexity and aesthetic finish.

The following are the most commonly used systems:

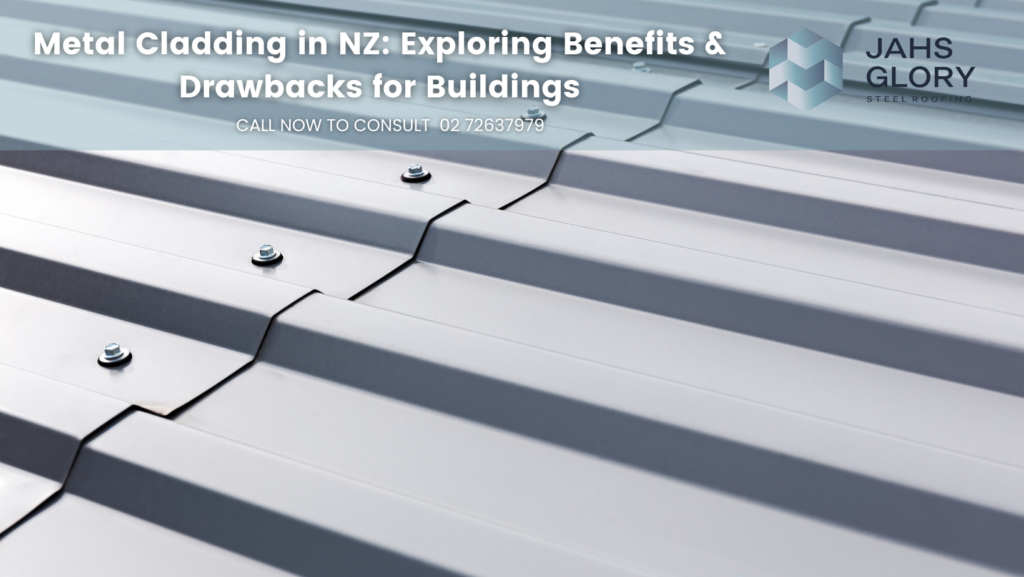

Standing Seam: Standing seam cladding, one of the most distinctive systems, is distinguished by sturdy folding connections between each panel. Because of its hidden fastening elements, it allows for streamlined architectural exteriors, making it a popular choice throughout typologies. Many other metals may be utilised with standing seam systems, including aluminium, galvanised or stainless steel, titanium, zinc, and weathering steel.

Snaplock: Snaplock is a simpler alternative to standing seam with a similar ribbed design but does not require specialised closing equipment to install. Snaplock panels are meant to “snap” together for a quick and easy installation.

Interlocking: An interlocking system provides a smoother look with dramatic, express joints. The width of interlocking metal cladding panels can vary and be designed to run horizontally, vertically, or diagonally.

Cassette: The open-jointed cassette system is ideal for large cladding areas and can accommodate panels up to 13 feet in length. The cassettes are bent and attached to an aluminium structure with invisible clips, resulting in a modern, flat look.

Custom: If none of the mentioned solutions is suitable for your project, a bespoke system can be created by a professional manufacturer by modifying an existing system or designing something entirely new. In this scenario, the project budget must be addressed because customisation would significantly raise the cost.

Materials

Metal cladding includes a wide range of materials. Various project-specific elements will impact your material selection, including intended aesthetic, climatic circumstances, structural system, nature of neighbouring materials, and construction budget. These materials are Stainless steel, Galvanised steel, Weathering steel, Aluminum, Titanium, Zinc, Copper and Brass.

JAHS Glory commits to providing quality work for each metal cladding project. We’ve lined up experienced professionals who value real craft, and we don’t rush as we take every step to get the job done right. We make sure each metal cladding project we do in Auckland lives up to everyone’s expectations.

Let our friendly, experienced professionals help you achieve that dream design without sacrificing durability. If you’re interested in finding out more about steel roofing or wall cladding for any commercial or residential properties, you can book a call here or drop us a message via jerome@jahsglory.co.nz.