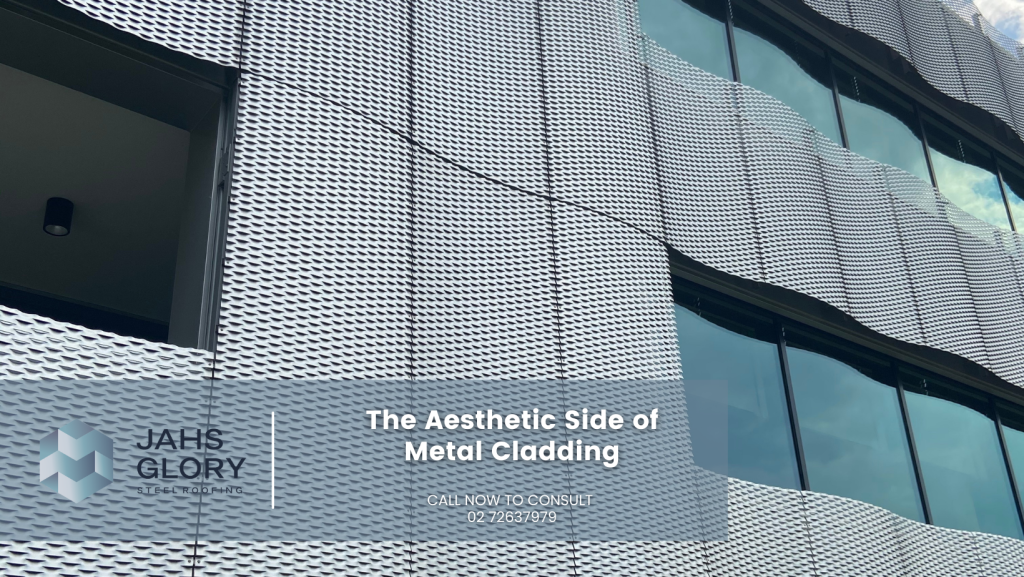

Metal cladding encompasses many different materials, each with unique strengths and weaknesses. Several project-specific factors will influence your material choice, including desired aesthetic, climatic conditions, chosen structural system, the nature of adjacent materials and the construction budget.

The following are among the most common material options for metal cladding:

Stainless Steel: Stainless steel is coated with a thin chromium oxide coating. The chromium aids in preventing the oxidization process of corrosion, making the material resistant to rust. Stainless steel is also popular due to its clean, polished appearance.

Weathering Steel: Weathering steel, also known as COR-TEN steel, is intended to develop a protective coating over time that has a constant rust-like appearance. This coating functions as a corrosion barrier and removes the need for painting. Its earthy, industrial look is appealing, but COR-TEN cladding must be properly finished to maintain a consistent patina over time.

Galvanised Steel: Galvanized steel is covered in a thin coating of zinc, which acts similarly to the chromium layer on stainless steel in preventing corrosion. Galvanized steel has a mottled appearance due to visible crystallites in the coating, which is known as “spangle.”

Zinc: Zinc is known for its weatherproof and corrosion-resistant capabilities. It is also resistant to UV rays and has self-healing properties, which means that if scratched, the material may cure itself over time.

Titanium: Architects like titanium because of its lightweight, great strength, and glossy, reflecting look. A protective oxide coating builds on the material’s surface over time, boosting its corrosion resistance. Upkeep is critical with titanium cladding; brown discolouration may occur if it is not adequately cleaned.

Aluminium: Because aluminium is inherently resistant to corrosion and blistering, it is a preferred cladding material for modern constructions. It also has a high strength-to-weight ratio, which makes aluminium façade attachment systems less bulky than steel panel attachment systems. However, the material is prone to denting and scratching and may corrode in certain climatic circumstances if not adequately cared for.

Brass: Brass is a very pliable cladding material that is ideally suited to ornamental sheet metal work because it strikes a balance between the chilly tone of zinc and the warmth of copper. As its surface oxidizes, brass develops a golden-brown patina.

Copper: Copper is another lightweight cladding choice that is exceptionally robust compared to other materials and is also 100% recyclable at the end of the building’s life. Its softly mirrored look oxidizes with time, turning the metal a characteristic green tint.

JAHS Glory commits to providing quality work for each metal cladding project. We’ve lined up experienced professionals who value real craft, and we don’t rush as we take every step to get the job done right. We make sure each metal cladding project we do in Auckland lives up to everyone’s expectations.

If you’re interested in finding out more about steel roofing or wall cladding for any commercial or residential properties, you can book a call here or drop us a message via jerome@jahsglory.co.nz.