Steel roofs are well-known for being non-corrosive which made them the most popular metal roof material used in residential and commercial properties.

You may wonder how it happens since it is a metal type of material that used to be corrosive in comparison to asphalt shingles. Steel roofs are non-corrosive due to their special physical and chemical properties. Below are the conditions that contractors are considering to identify the grade of steel to be used.

Environment Conditions

There are several types of alloy being used in different environments. Here’s what to observe in the area, to understand the steel grade of the roof to be used:

- Frequency of rainfall

- The temperature in the area

- Industrial Activity

- Pollution

- Coastal Areas

- Areas with high Chlorides, Sulphur Dioxide, and Fluorides

Those six on the list could be quite technical, and JAH’s Glory is here to help in creating several design decisions and deliver high-quality steel roofing and wall cladding service. We also offer a no-obligation, free discovery call to provide you with advice with regard to the service you needed.

Chemical Grade

There is a material standard for steel sheets, it is the EN 10088-2 which was issued in 1995. There is a total of 17 material grades, which helps the steel roof become more tolerant to the chemical composition in the area. Below is the Technical Guide from http://www.worldstainless .org:

1.4510/ 1.4301 Grade is a low class being used for Rural areas with frequent rainfall, and/or high temperature. Urban Areas with low industrial activity and without significant pollution. These are typically tin coated.

1.4401/ 1.4404/ 1.4435/ 1.4436/ 1.4432 grade is medium class material used in urban areas with higher pollution, industrial and coastal areas with higher rainfall.

1.4439/ 1.4539/ 1.4547/ 1.4462 (Duplex) grade is a high-class material used in areas of higher risk where chlorides, Sulphur dioxide, fluorides also occur. Industrial or coastal areas with high temperatures. Care should be taken to avoid crevices that might allow corrosive material and etcetera to accumulate.

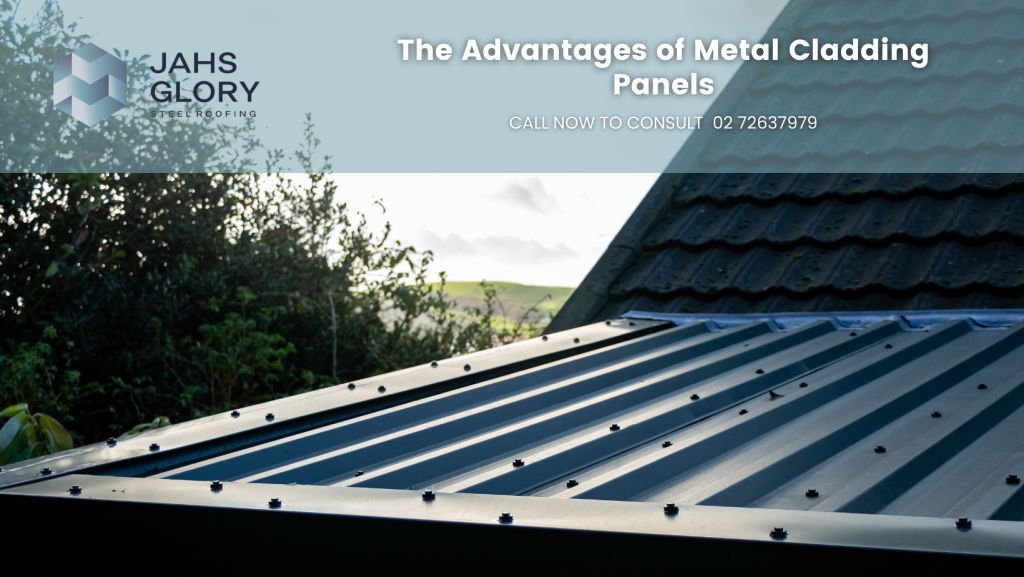

Surface Finish

There is a total of six types of surface finish and there are:

- 2B

- Matt

- Patterned

- Terne-coated

- PVDF Coated

- Electrolytically colored

Most commonly used in residential properties is the 2B finish, which is reflective, smooth, and has a flat surface. This type of texture made it resistant to corrosion, and maintenance is easier.

Second, most used is matt finish, which can be obtained by a cold rolling process.

For a steel roof to be more tolerant to corrosion, the general rule is to have a smoother surface microstructure, the better resistance grade. For now, we will be presenting two types of surface finish and will include the other in the next articles.

Environment conditions, chemical grade, and surface finish are things that your roofing contractors are checking, to maximize the steel roof benefits, and give the best roofing type in your area.

Contacts Us

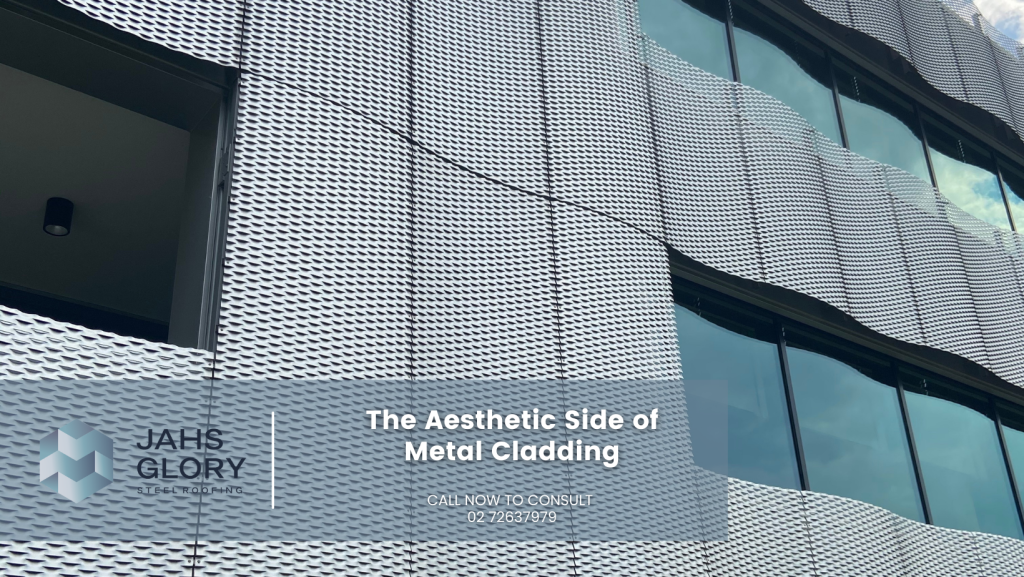

You can get the most out of steel roofing and wall cladding when professionals with high regard to safety and health protocols deliver the best service to you.

JAHS Glory commits to providing quality work for each steel roofing or wall cladding project. We’ve lined up experienced professionals who value real craft, and we don’t rush, as we take every step to get the job done right. We make sure each steel roof and wall cladding project we do in Auckland lives up to everyone’s expectations.

Let our friendly, experienced professionals help you achieve that dream design without sacrificing durability. If you’re interested in finding out more about steel roofing or wall cladding for any commercial or residential properties, you can book a call here or drop us a message via jerome@jahsglory.co.nz.